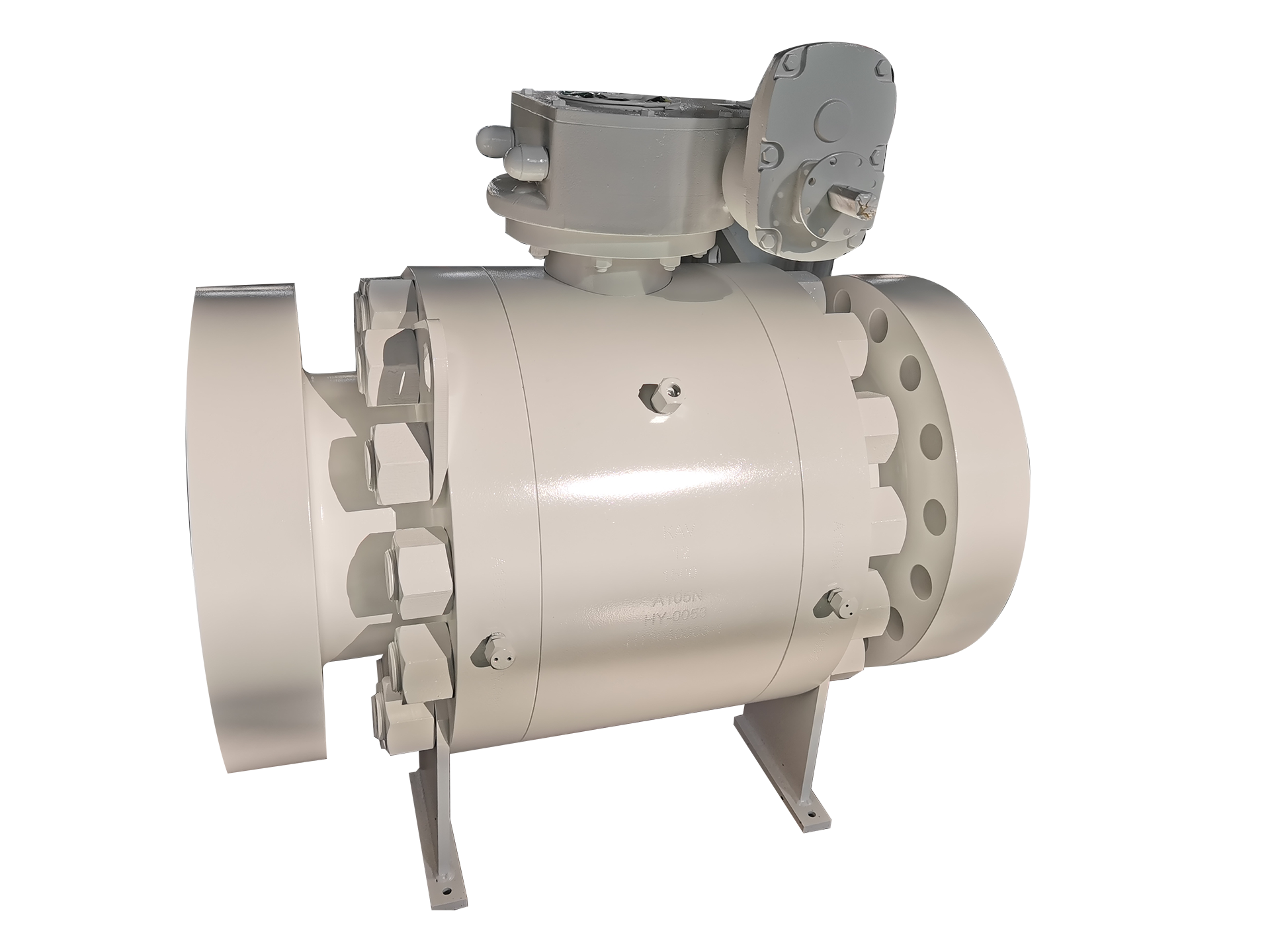

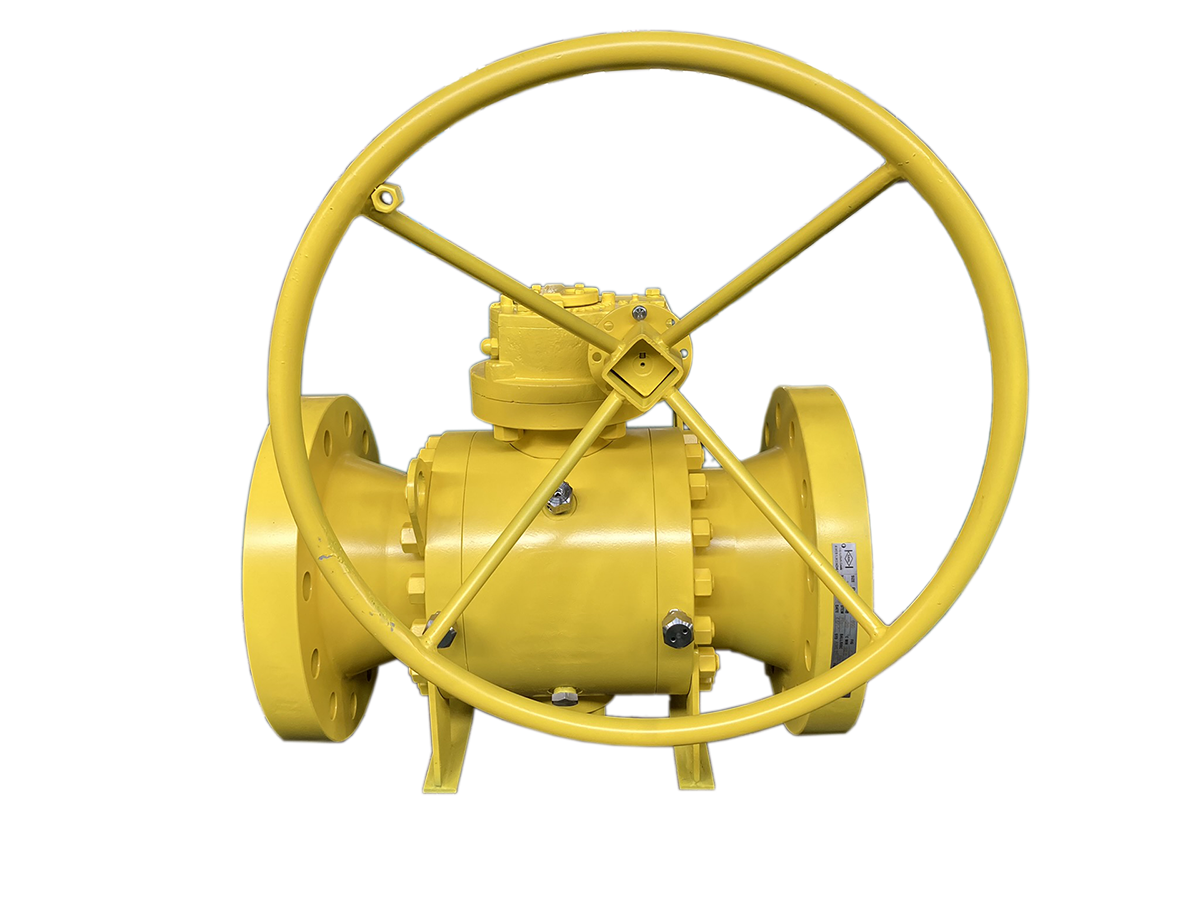

TRUNNION BALL VALVES

Kaval trunnion ball valves are engineered for reliable shutoff and efficient flow control, with a straight-through design that minimizes pressure drop and turbulence. The ball is supported by trunnions, allowing smooth 90-degree rotation and reduced operating torque.

Compared to floating ball valves, trunnion-mounted designs are better suited for both low- and high-pressure applications, offering enhanced sealing, lower energy consumption, and longer service life.

Kaval offers a complete line of trunnion ball valves designed to meet the demanding performance standards of the oil & gas, power, chemical, and petrochemical industries. Other valve production