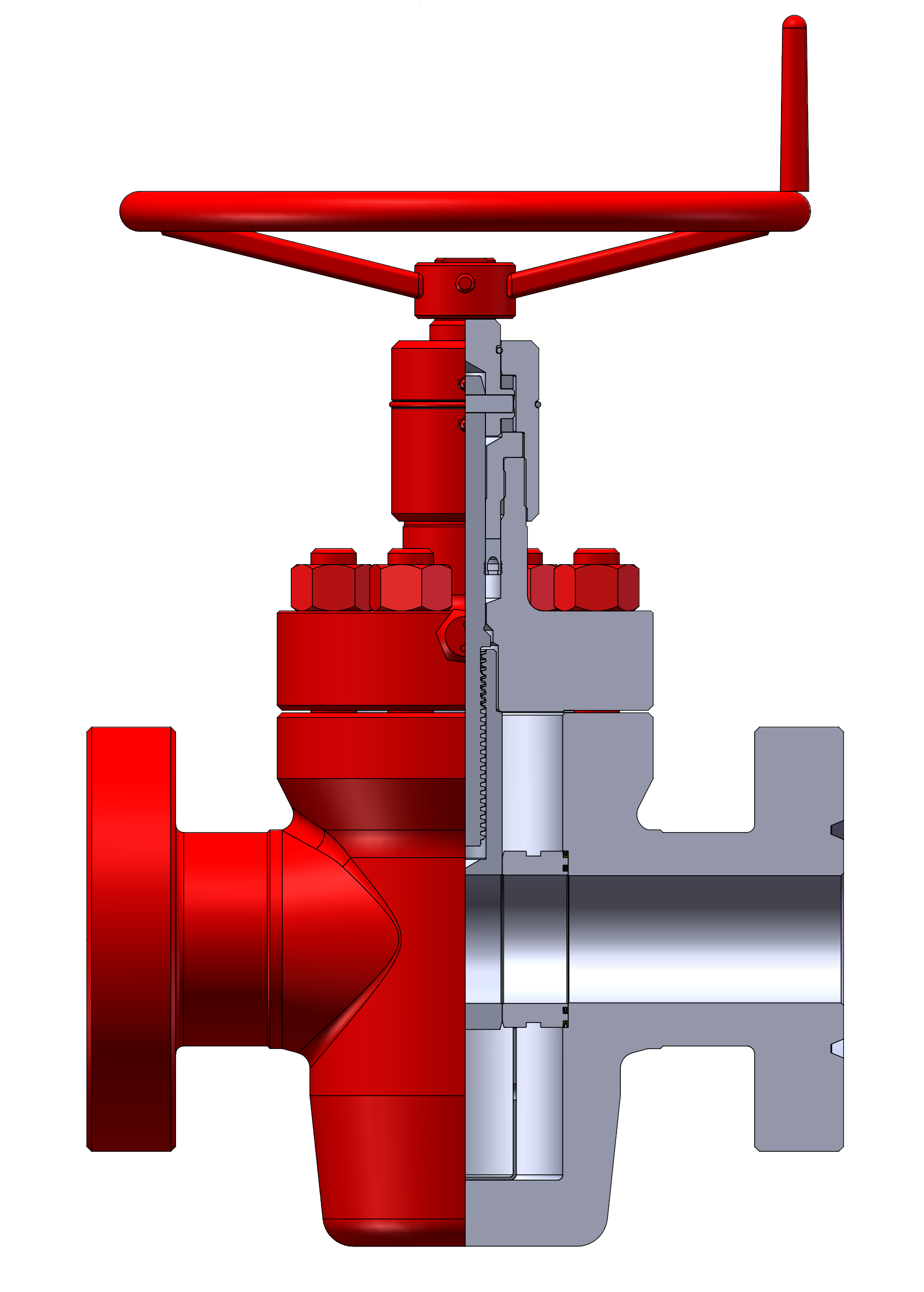

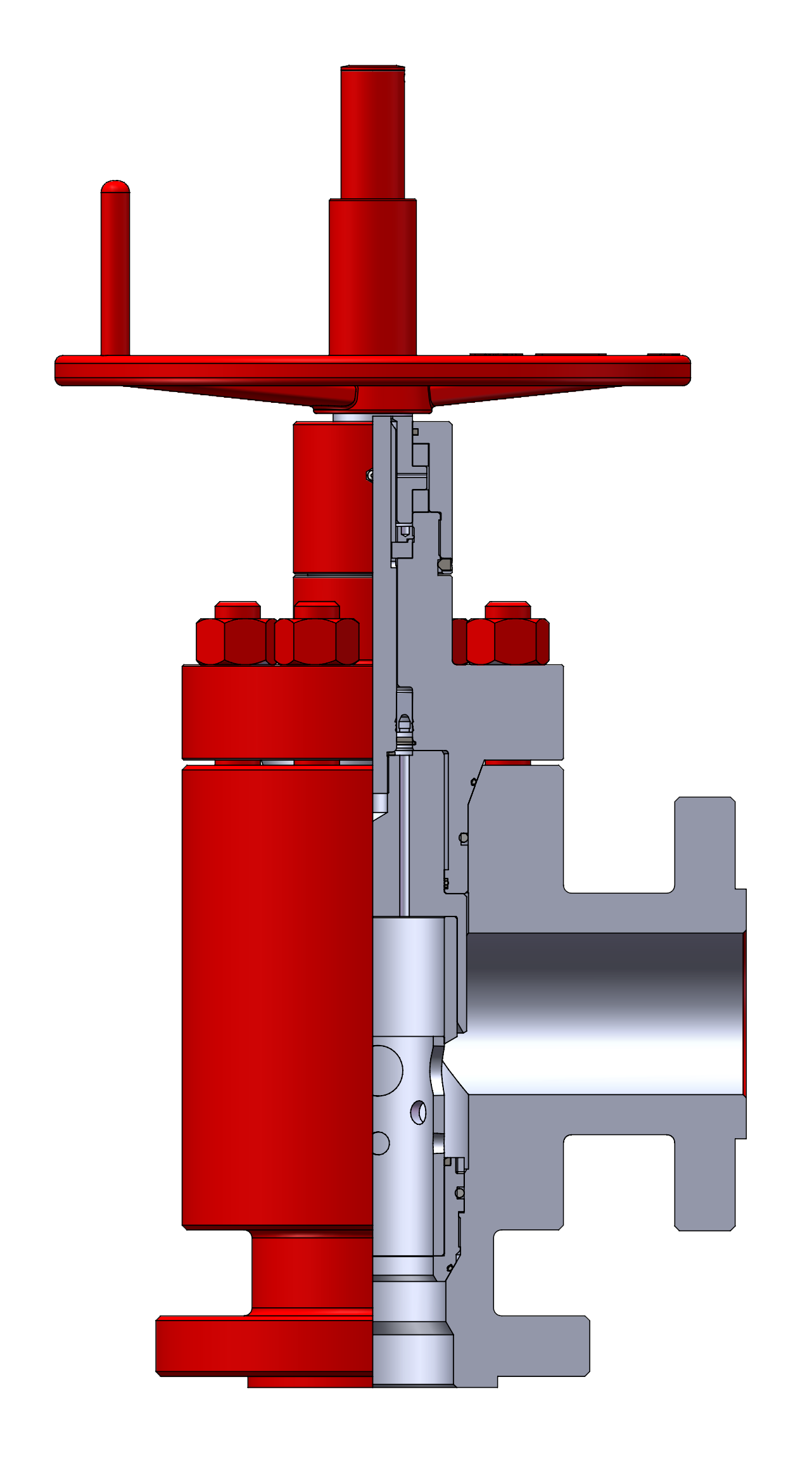

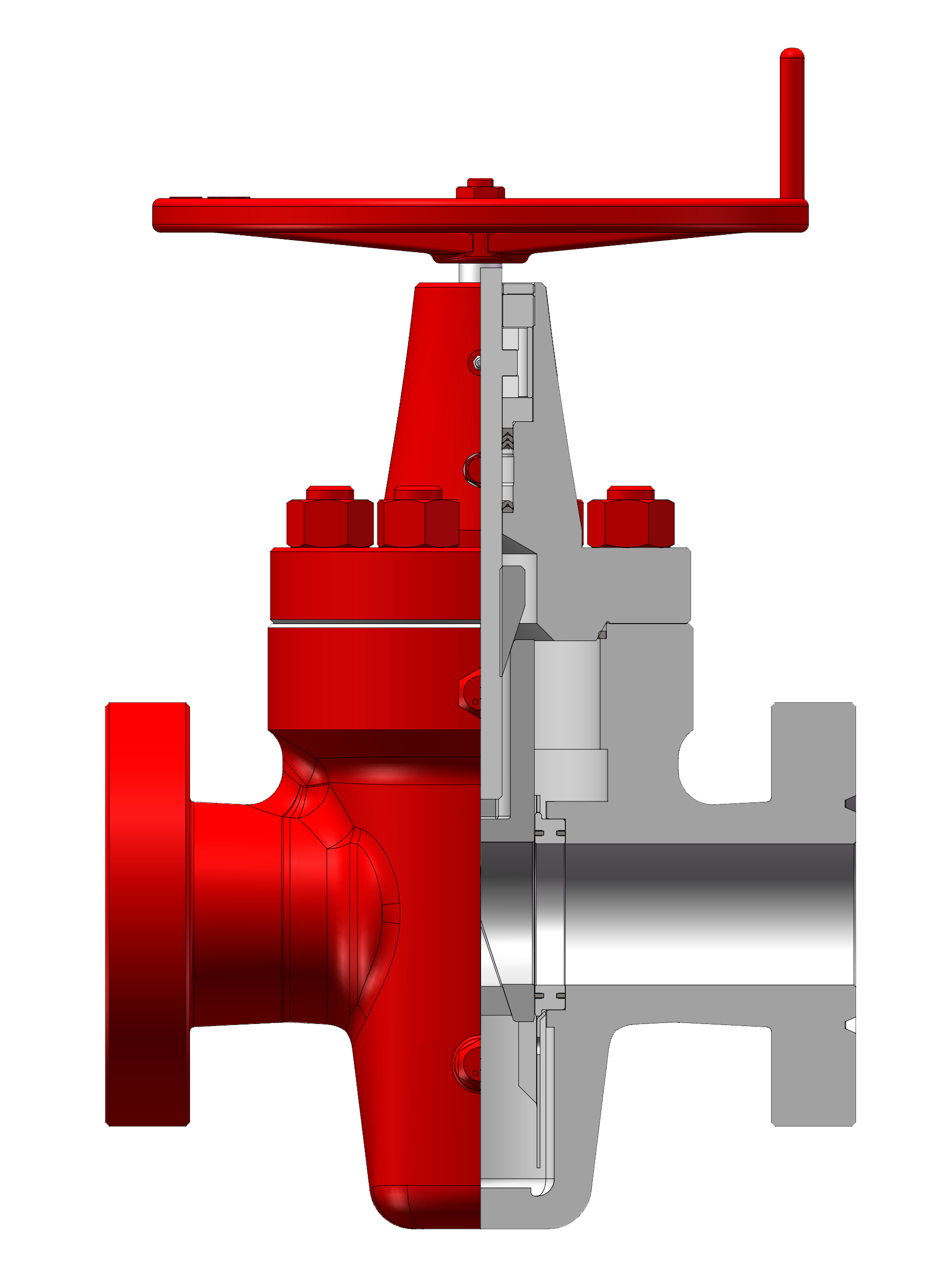

API 6A Valve

Kaval API 6A valves are designed and manufactured to meet the stringent requirements of wellhead and Christmas tree applications in the oil and gas industry. Built for high performance, these valves ensure safety, reliability, and long service life in high-pressure and high-temperature environments.

Our API 6A valves are fully compliant with the latest API 6A standards and are suitable for a range of critical upstream operations, including production, drilling, and injection systems.

We offer a variety of configurations, trims, and pressure ratings to meet your operational needs. If your project requires a custom solution, our engineering team is ready to provide tailored valves that meet your exact specifications.