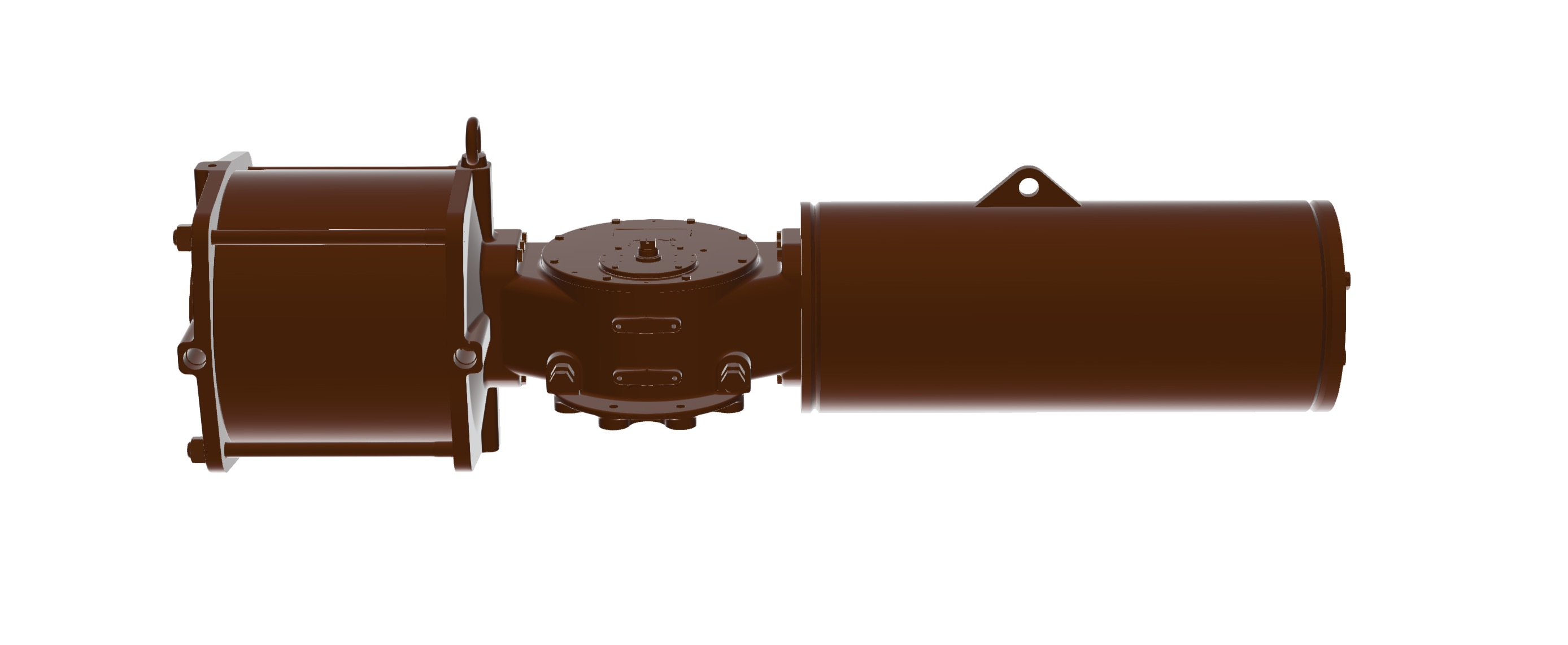

ACTUATOR

Kaval pneumatic actuators are engineered for reliability, precision, and long-term performance in demanding industrial applications. Designed to operate seamlessly with our valve products, they deliver consistent and efficient actuation for use in oil and gas, petrochemical, power generation, and other critical systems.

Built to perform in high-pressure and harsh environments, our actuators offer dependable automation and control.

We specialize in pneumatic actuation and provide a range of models to suit various torque and control requirements. If your project has specific needs, our team is ready to collaborate with you on customized solutions that ensure optimal system performance.